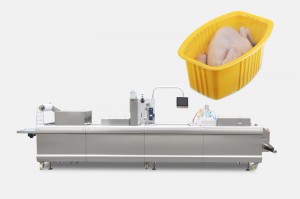

Semi-automatic tray sealer FG-040

The small semi-automatic tray sealers are the ideal solution for an inexpensive and professional vacuum packaging with trays and combine ease of use with reliability. They are ideally suited as an entry machine into tray packaging for smaller businesses or as an addition in larger productions or laboratories to cover samplings and new product launches.

After inserting the filled trays and closing the vacuum chamber, everything continues automatically, from evacuation, optional to do modified atmosphere packaging or skin packaging, to sealing and precise contour cutting of the trays.

1, 2-3 cycles/min speed.

2, Attractive package with top MAP or VSP technology(Unifresh®)。

3, All features controlled by servomotor with high speed and precision.

4, With Busch vacuum pump, we can make residual oxygen lower than 1%.

5, Applied to trays of various shapes and sizes.

6, Remarkable film wastage saving.

UTIENPACK tray sealers can handle different types of packaging in order to pack a wide range of products.

Natural atmosphere

This is a packaging type for no gas exchange, seal the packaging directly. There is no effect of extending shelf life.

MAP Pack

The natural gas in the package is replaced with the product-specific gas. This protects the product and also extends the shelf life of the food.

Pseudo-skin

The pseudo-skin technique applies to the product whose thickness is less than the tray depth. The skin film is applied to the product and sealed tightly in the tray.

Protrude Skin

The Protrude Skin technology packs products in a skin package, the height of the product can reach 50 mm. The packaged product is often higher than the tray.

This product is also precisely enclosed by the film and seals the tray on the whole surface.

Utien Pack Tray sealer is perfect for the package of fresh, refrigerated and frozen food, ncluding meat, poultry,seafood, sausages, bacons and prepared fast food.According to different products, we’re capable to offer you tailor-made packaging proposals.

1.Vacuum pump of German Busch, with reliable and stable quality

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Model | FG-040 |

| Packaging Option | MAP, VSP, SEAL |

|

Cycle/min,MAP Cycle/min,VSP Cycle/min,Seal |

2~3 2~3 5 |

| Vacuum Pump | 100m³/h |

| Film Size | ≤300mm |

| Power | 380V |

| Gas Replacement Rate | ≥99% |

| Filling Gas Option | 3(N2, CO2, O2) |

| Machine size | 910×1150×1720mm |

| Film |

Transparent Top Film Pre-printed Top Film |

| Tray material |

PSE, PP |