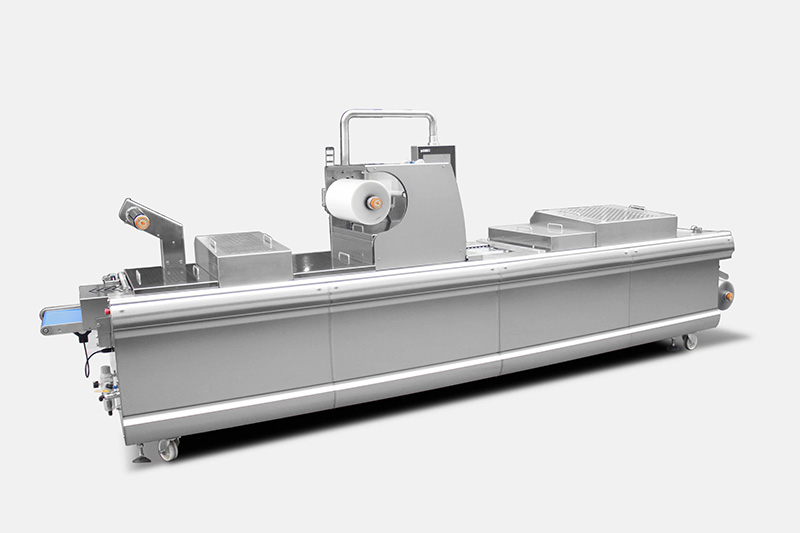

OEM/ODM Factory Vacuum Sealer For Blankets - Vertical External Vacuum Packaging Machine – Utien Pack

OEM/ODM Factory Vacuum Sealer For Blankets - Vertical External Vacuum Packaging Machine – Utien Pack Detail:

1.Using PLC control system, the vacuum and heat sealing cooling time can be adjusted accurately, and multiple formula parameters can be stored for different product packaging requirements.

2.The working head can be adjusted up and down.

3.The external structure of the whole machine is made of 304 stainless steel.

4.Can be customized according to customer requirements, the length of the seal can be up to 1200mm.

5.Can be used with a conveyor line.

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of OEM/ODM Factory Vacuum Sealer For Blankets - Vertical External Vacuum Packaging Machine – Utien Pack , The product will supply to all over the world, such as: Georgia, Moscow, Cambodia, We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

It’s able to handle a variety of thermoplastic material and poly-coated fabrics,such as tarpaulins, billboards,tents,awnings,inflatalbes,truck covers,and more.

Extension table

4 pieces in 1 set.Intend to hold the banner whcih ensures that the two end of the welding is smooth and can slide to the next weld.

New measurement system

A block piece help placing the banner

Tape roller support with self brake

Suitable for overlap weld with tape on one side.

Kedar holder

Hold the kedar to ensure the precise weld with no deflection.

Laser light

Mark on the welding bar to show the position where the banner should be.

Piston holder

A holding bar with piston pressure which hold the position of the banner incase that it moves before welding.

| Machine model | FMQP-1200/2 |

| Power(kW) | 2.5 |

| Voltage(V/Hz) | 220/50 |

| Air source(Mpa) | 0.6 |

| Sealing length(mm) | 1200 |

| Sealing width(mm) | 10 |

| Size(mm) | 1390×1120×1250 |

| Weight(kg) | 360 |

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!