OEM/ODM China Map Tray Sealer - Continuous automatic tray sealer – Utien Pack

OEM/ODM China Map Tray Sealer - Continuous automatic tray sealer – Utien Pack Detail:

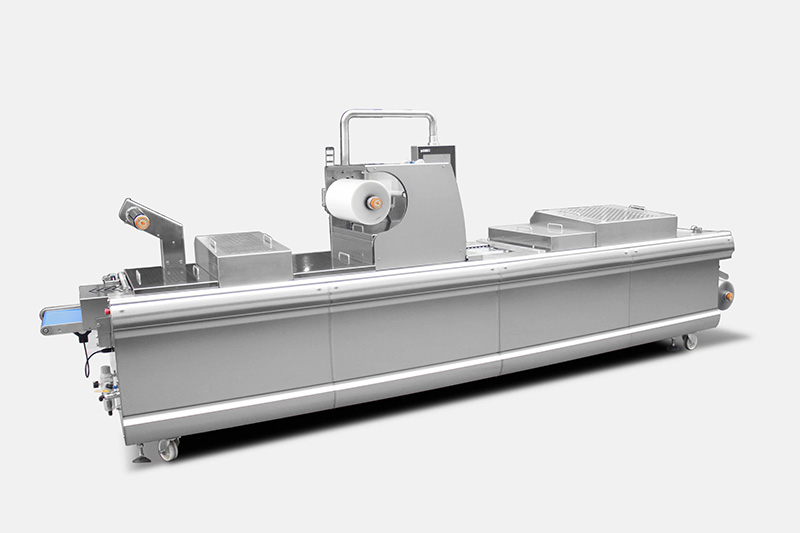

Whether as a single packaging machine or integrated into highly automated and complex packaging lines include any automatic dosing and labelling units., Continuous automatic tray sealer from UTIENPACK are the ideal solution for high packaging volumes and can also be integrated into automated packaging lines in stages.

The accessible applications are numerous, from simple sealing to vacuum, MAP and various types and classes of packaging skin. The PLC touchscreen interface is simple and intuitive, making it easy to use even for inexperienced personnel. In addition, thehigh degree of customisation of the machine’scomponents ensures that it can be applied to any type of product to be packaged. Reliability, ease of cleaning and maintenance, easy programming and a wide range of customisation options are just some of its strengths.

1, 6-8 cycles/min speed.

2, Attractive package with top MAP or VSP technology(Unifresh®)。

3, All features controlled by servomotor with high speed and precision.

4, With Busch vacuum pump, we can make residual oxygen lower than 1%.

5, Applied to trays of various shapes and sizes.

6, Remarkable film wastage saving.

Product detail pictures:

Related Product Guide:

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for OEM/ODM China Map Tray Sealer - Continuous automatic tray sealer – Utien Pack , The product will supply to all over the world, such as: Romania, Spain, Sevilla, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

It has been widely applied in cosmetic, chemistry and food industries.

Ultrasonic welding can be applied to almost all plastic material, as it creates heat by way of friction between the materials to be joined.

1.Auto tube loading

The plastic tube is placed in the collecting tank with the opening outward. The swing mechanism controls the tube to enter the tube drop channel one by one, and the tube dropping mechanism swings back and forth 90° to place the tube into the lower tube base to complete the tube loading.

2.Auto orientation

After the tube is loaded, the rotary table to drive the tube to the marking station. The position of the tube is adjusted by identifying the positioning mark on the tube through the photoelectric switch. Keep all tubes facing in the same direction.

3.Auto filling

The filling part is composed of filling head, material tank, etc. The piston is driven to move by the pneumatic parts to extrude the material and pour it into the lower tube from the material tank. It can accurately controlled by controlling the extrusion time, and automatic filling can be realized from 20g to 250g.

4.Ultrasonic sealing

Plastic molecules are vibrated and strongly jointed together with ultrasonic power to achieve the purpose of sealing, it can be sealed under different conditions. It can be firm and nice welding regardless of the material remaining on inner wall of the tubes or there is water at the sealing place, and it is not easy to produce false seal.

5.Cutting surplus edge

Automatic edge cutting, cutting off the surplus edge at the end of the tube after sealing, making the end more smooth, can be cut out a variety of different shapes or lines of the tail to meet the design requirements.

1.The 304 stainless steel body shell of the whole machine meets the requirements of food hygiene.

2.PLC control module is adopted to make the operation of the equipment simple and convenient.

3.It adopts SMC pneumatic components from Japan, with accurate positioning and low failure rate.

4.Adopt French Schneider electrical components to ensure long-term operation.

| Machine Model | DGF-25C |

| Voltage (V/HZ) | 220/50 |

| Power (kw) | 1.5 |

| Speed (pcs/min) | 0-25 |

| Sealing Width (mm) | 3-6 |

| Sealing Length (mm) | <85 (φ50) |

| Matching Air Pressure(Mpa) | 0.4-0.8 |

| Dimensions (mm) | 900×800×1650 |

| Weight (kg) | 260 |

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!