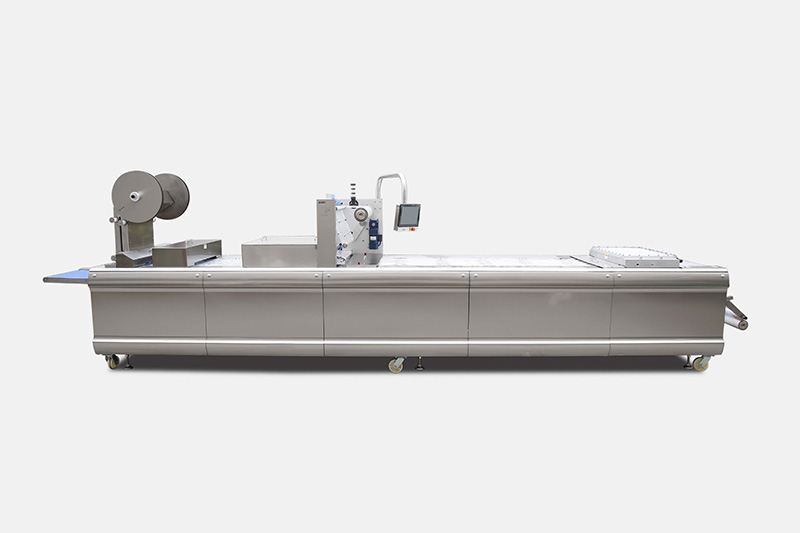

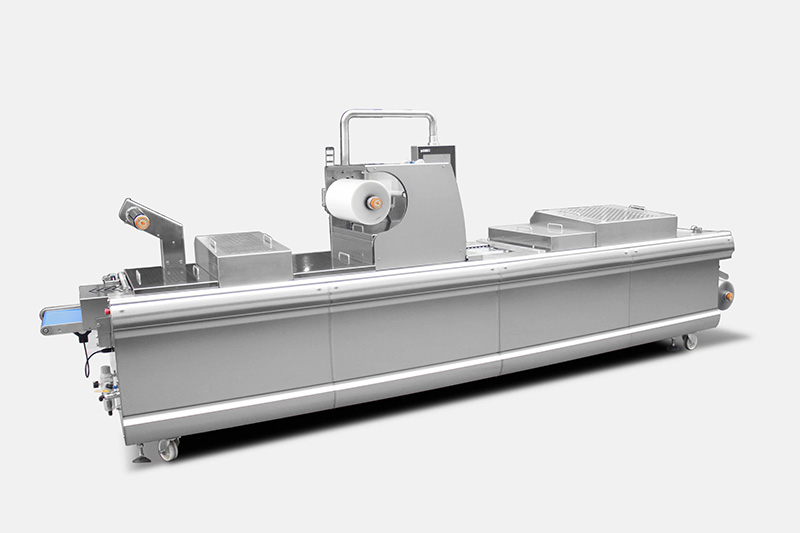

OEM Manufacturer Condiment Packaging Machine - Thermoforming vacuum skin packaging machine(VSP) – Utien Pack

OEM Manufacturer Condiment Packaging Machine - Thermoforming vacuum skin packaging machine(VSP) – Utien Pack Detail:

Safety

Safety is our top concern in machine design. To ensure max safety for the operators, we have installed multiply sensors in many parts of the machine, including protective covers. If the operator opens the protective covers, the machine will be sensed to stop running immediately.

High-efficiency

High efficiency enables us to make full use of the packaging material and reduce cost & waste. With high stability and reliability, our equipment can reduce downtime, thus the high production capacity and uniform packaging result can be ensured.

Simple operation

Simple operation is our key feature as a highly automated packaging equipping. In terms of operation, we adopt PLC modular system control, which can be acquired through short-time learning. Besides machine control, mold replacement and daily maintenance can also be mastered easily. We’re keeping on technology innovation to make machine operation and maintenance as easy as possible.

Flexible

To fit into various products, our excellent packaging design can custom the package in shape and volume. It grants customers better flexibility and higher utilization in the application. The packaging shape can be customized, such as round, rectangular and other shapes.

Special structure design can also be customized, such as hook hole, easy tear corner, etc.

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for OEM Manufacturer Condiment Packaging Machine - Thermoforming vacuum skin packaging machine(VSP) – Utien Pack , The product will supply to all over the world, such as: Liberia, Paraguay, Libya, We've more than 10 years exported experience and our products and solutions have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoforming rigid film packaging machine is mainly used for modified atmosphere packaging (MAP) of products. The natural air in the packaging is replaced with fresh-keeping gases.

Advantages of MAP packaging

·Extend the shelf lifetime;

·Offer more protection during transportation;

·Keeping food fresh naturally without any additives;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

Multi-head weighing system

· Ultraviolet sterilization system

· Metal Detector

· Online automatic labeling

· Gas Mixer

· Conveyor system

· Inkjet printing or thermal transfer system

· Automatic screening system

…

1.Vacuum pump of German Busch, with reliable and stable quality .

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation.

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Mode | DZL-420Y |

| Speed(cycles/min) | 6-8 |

| Packaging option | Rigid,or semi-rigid film,MAP |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <500 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 13.5 |

| Machine dimensions(mm) | 4600×1160×1900,Customizable |

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!