Ultrasonic tube sealers are advanced machinery for efficient sealing of tubes. With their innovative features and cutting-edge technology, they offer many advantages that make them stand out in the market. In this article, we will discuss the main advantages that ultrasonic tube sealers have.

One of the remarkable advantages of the ultrasonic tube sealing machine is its PLC control system, which is easy to operate. This feature enables the user to easily navigate through the machine's settings and control various parameters. The user-friendly interface ensures that even beginners can quickly master the system's functions, reducing the training time required.

In addition, the ultrasonic frequency equipped with the ultrasonic sealing machine has advanced continuous scanning and automatic correction functions. This feature enables the machine to accurately adapt to different pipe materials and sizes. Ensure consistent, reliable seals every time by automatically adjusting sealing parameters. This stability is critical in industries where product quality is critical.

Another advantage of the ultrasonic sealing machine is the automatic error alarm function. This feature alerts the operator if there are any failures or errors during the sealing process. With timely notifications and visual indicators, operators can resolve issues immediately, preventing further production delays or product damage. This capability has proven invaluable for maintaining a smooth workflow and preventing costly downtime.

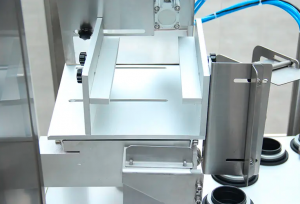

The new automatic tube loading mechanism is another noteworthy feature of the ultrasonic tube sealing machine. This mechanism ensures a seamless loading process without any interruptions. It eliminates manual work and significantly reduces the possibility of human error. The tube loading mechanism is perfectly synchronized with the sealing process, increasing productivity and efficiency.

In addition to these advantages, ultrasonic tube sealers also have some other advantages. They produce a clean, precise seal without the need for additional sealants such as adhesives or solvents. This reduces overall production costs and eliminates any potential health hazards associated with these chemicals. Additionally, ultrasonic sealing is a non-contact process, which means minimal wear and tear on the machine, reducing maintenance costs.

Ultrasonic tube sealers are also very versatile, capable of sealing a wide variety of tubing materials, including plastics, laminates, and metals. This versatility makes them suitable for use in various industries such as cosmetics, pharmaceuticals, food and household goods.

Additionally, ultrasonic tube sealers provide significant time savings compared to traditional sealing methods. Advanced technology ensures fast and efficient sealing, reducing production time and increasing overall output.

In conclusion, ultrasonic tube sealing machines have several advantages that are different from traditional sealing machines. With their PLC control system, advanced scan frequency, automatic error alarm function and novel tube loading mechanism, they offer exceptional ease of use, reliability and efficiency. These machines not only increase productivity, but also ensure consistent high quality seals. With their many advantages, ultrasonic tube sealers are an excellent choice for industries looking to optimize their sealing process.

Post time: Jul-27-2023