Packaging plays an important role in attracting customers and displaying products in an attractive manner. As the retail industry becomes increasingly competitive, it is critical for manufacturers and retailers to invest in packaging solutions to enhance the shelf appeal of their products. Thermoforming packaging machines have become a game-changer in this regard, offering multiple advantages that help improve the overall appeal of the product.

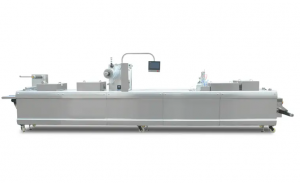

Thermoforming is a manufacturing process that uses heat to form plastic into various shapes, creating packaging solutions that are not only visually appealing but also functional. Thermoforming packaging machines have revolutionized the packaging industry by enabling manufacturers to create custom-designed packaging that perfectly fits their products.

One of the main advantages of thermoforming packaging machines is the ability to create packages with complex designs and shapes. This opens up endless possibilities for manufacturers to create unique packaging that stands out on the shelf. Whether it’s bold, eye-catching shapes or packaging with smooth curves and contours, thermoforming machines can turn any design concept into reality.

Another important aspect of thermoforming packaging machines is the versatility they offer when it comes to materials. These machines can process a wide range of plastics, including PET, PVC and PP, allowing manufacturers to choose the material that best suits their product requirements. Each plastic material has its own set of properties, such as transparency, durability and barrier protection, which can be used to enhance the overall packaging appeal.

The ability to incorporate various visual elements into packaging designs is another advantage of thermoforming packaging machines. These machines can create packaging with embossed logos, textured surfaces and even holographic effects, adding an extra layer of sophistication and uniqueness to the product. These visually appealing features capture customers' attention and create memorable experiences, resulting in increased sales and brand loyalty.

In addition to visual appeal, thermoforming packaging machines also help improve the functionality of packaging. These machines can create packages with specific features, such as easy-open labels, reclosable seals and divider designs, making packaging more user-friendly and convenient. Functionality is a key factor when consumers choose products, and thermoforming packaging machines enable manufacturers to meet these needs.

Additionally, thermoforming packaging machines offer efficient production capabilities, allowing manufacturers to meet high demand efficiently. These machines are able to produce packaging at a faster rate, thereby reducing production time and costs. Not only does this benefit manufacturers, it also ensures retailers have a steady supply of products, reducing the likelihood of out-of-stock situations that could be detrimental to sales.

In summary, thermoforming packaging machines have revolutionized the packaging industry by enhancing the shelf appeal of products. The ability to create unique designs, utilize a variety of materials, incorporate visual elements and improve functionality makes thermoforming packaging machines valuable assets for manufacturers and retailers. Investing in these machines can increase product sales, customer satisfaction and brand recognition in today's competitive market.

Post time: Sep-14-2023