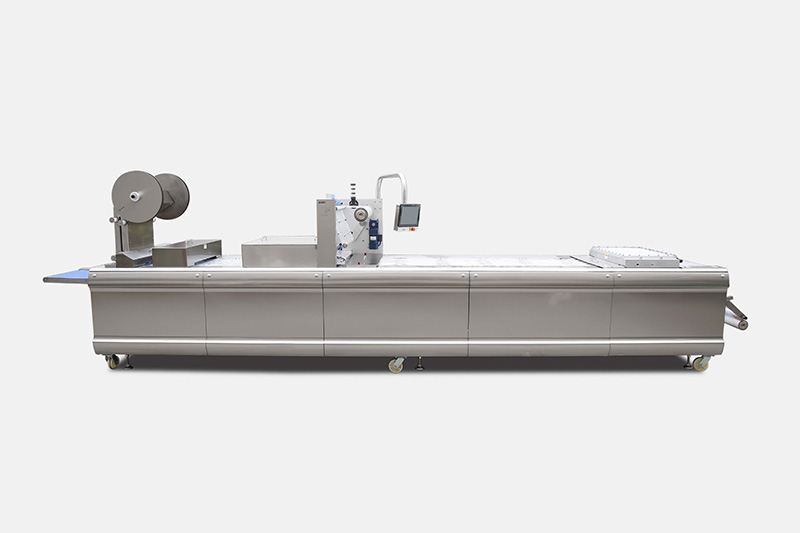

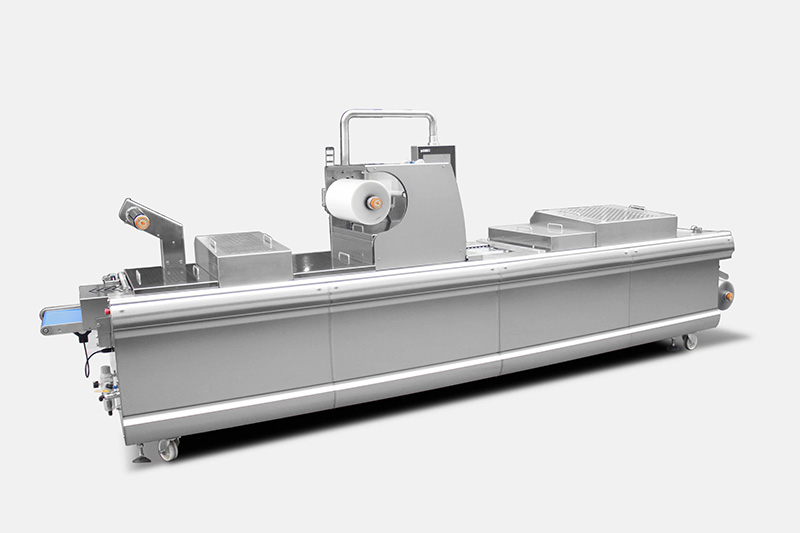

New Arrival China Vacuum Tray Sealer - Semi-automatic tray sealer – Utien Pack

New Arrival China Vacuum Tray Sealer - Semi-automatic tray sealer – Utien Pack Detail:

The small semi-automatic tray sealers are the ideal solution for an inexpensive and professional vacuum packaging with trays and combine ease of use with reliability. They are ideally suited as an entry machine into tray packaging for smaller businesses or as an addition in larger productions or laboratories to cover samplings and new product launches.

After inserting the filled trays and closing the vacuum chamber, everything continues automatically, from evacuation, optional to do modified atmosphere packaging or skin packaging, to sealing and precise contour cutting of the trays.

1, 2-3 cycles/min speed.

2, Attractive package with top MAP or VSP technology(Unifresh®)。

3, All features controlled by servomotor with high speed and precision.

4, With Busch vacuum pump, we can make residual oxygen lower than 1%.

5, Applied to trays of various shapes and sizes.

6, Remarkable film wastage saving.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for New Arrival China Vacuum Tray Sealer - Semi-automatic tray sealer – Utien Pack , The product will supply to all over the world, such as: Sierra Leone, Amsterdam, Dubai, Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoforming rigid film packaging machine is mainly used for modified atmosphere packaging (MAP) of products. The natural air in the packaging is replaced with fresh-keeping gases.

Advantages of MAP packaging

·Extend the shelf lifetime;

·Offer more protection during transportation;

·Keeping food fresh naturally without any additives;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

Multi-head weighing system

· Ultraviolet sterilization system

· Metal Detector

· Online automatic labeling

· Gas Mixer

· Conveyor system

· Inkjet printing or thermal transfer system

· Automatic screening system

…

1.Vacuum pump of German Busch, with reliable and stable quality .

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation.

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Mode | DZL-420Y |

| Speed(cycles/min) | 6-8 |

| Packaging option | Rigid,or semi-rigid film,MAP |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <500 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 13.5 |

| Machine dimensions(mm) | 4600×1160×1900,Customizable |

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.