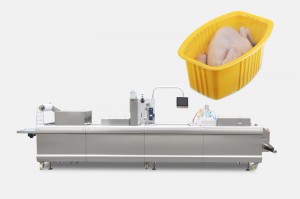

Instant Food Thermoforming Vacuum Packing Machinery with CE

• 304 Stainless steel construction make the machine longer lifetime.

• Advanced film infeeding system make the rolling film smooth and strong enough for thermoforming.

• Large touch screen PLC operating system,user friendly, self-explanatory machine interface

• Maximum safety protection.All the function section is covered with steel cover prevent worker from being hurt.

• Customizable in size,loading area,printing area adjustable for special need.

• Patent punch cutting mold can make the edge of tray much more smooth.

• With the most advanced technology of thermoforming system, packing depth can reach 160mm (max).

This machine is mainly used for vacuum or modified atmosphere packaging of products to extend the shelf life of products. Oxidation is slow in the package under vacuum or modified atmosphere, which is a simple packaging solution. It can be applied to the products in the food industry such as snack food, chilled fresh meat, cooked food, medicine, and daily chemical products.

|

|

|

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

- Multi-head weighing system

- Ultraviolet sterilization system

- Metal Detector

- Online automatic labeling

- Gas Mixer

- Conveyor system

- Inkjet printing or thermal transfer system

- Automatic screening system

| Machine Parameters | |

| Machine mode | DZL-R series |

|

Packing speed |

7-9 cycles/min |

| Packing type | Flexible film,vacuum or vacuum gas flush |

| Packing shape | Customized |

| Film width | 320mm-620mm( customized) |

| Max depth | 160mm ( depends) |

| Machine advance | <800mm |

| Power | Around 12kW |

| Machine size | Around 6000×1100×1900mm, or customized |

| Machine body material | 304 SUS |

| Mold material | Quality anodized aluminum alloy |

| Vacuum Pump | BUSCH(Germany) |

| Electrical Components | Schneider(French) |

| Pneumatic Components | SMC(Japanese) |

| PLC Touch Screen & Servo Motor | DELTA(Taiwan) |