Hot Sale for Quiet Vacuum Sealer - Cabinet Vacuum Packaging Machine – Utien Pack

Hot Sale for Quiet Vacuum Sealer - Cabinet Vacuum Packaging Machine – Utien Pack Detail:

1. The unique structure design can vacuum (inflate) packaging of ultra-fine powder, granule, liquid and slurry.

2. The barrels for shaping the products can also be placed in the vacuum chamber.

3. Using PLC control system, a variety of special functions can be used flexibly.

4. The vacuum chamber is made of 304 stainless steel, and the shell material is available in spray paint, suitable for various occasions and material packaging.

5. With a high-strength plesiglass chamber door, all the packaging process is transparenct and trackable.

6. The vacuum degree is high and can be adjusted easily by a vacuum gauge.

7. The control system adopts PLC control, and the vacuum delay, heating time and cooling time can be accurately controlled.

8. Special specifications can be customized.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Hot Sale for Quiet Vacuum Sealer - Cabinet Vacuum Packaging Machine – Utien Pack , The product will supply to all over the world, such as: Hungary, Colombia, Argentina, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

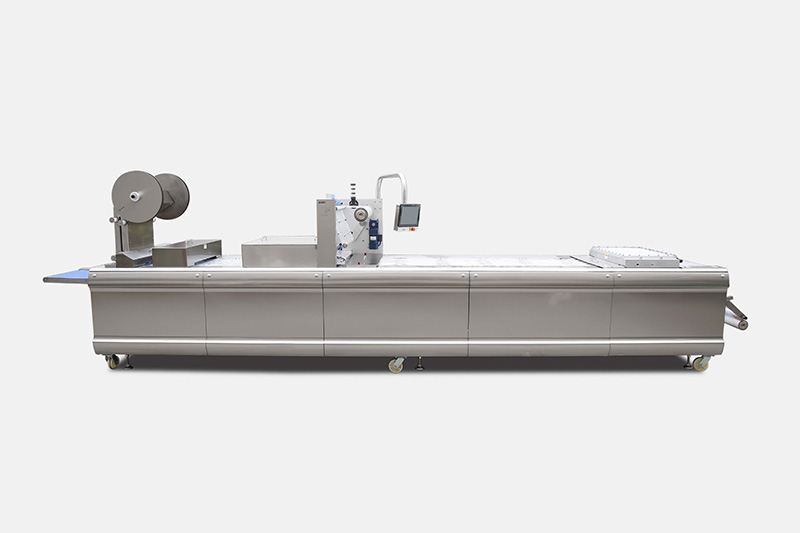

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoforming rigid film packaging machine is mainly used for modified atmosphere packaging (MAP) of products. The natural air in the packaging is replaced with fresh-keeping gases.

Advantages of MAP packaging

·Extend the shelf lifetime;

·Offer more protection during transportation;

·Keeping food fresh naturally without any additives;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

Multi-head weighing system

· Ultraviolet sterilization system

· Metal Detector

· Online automatic labeling

· Gas Mixer

· Conveyor system

· Inkjet printing or thermal transfer system

· Automatic screening system

…

1.Vacuum pump of German Busch, with reliable and stable quality .

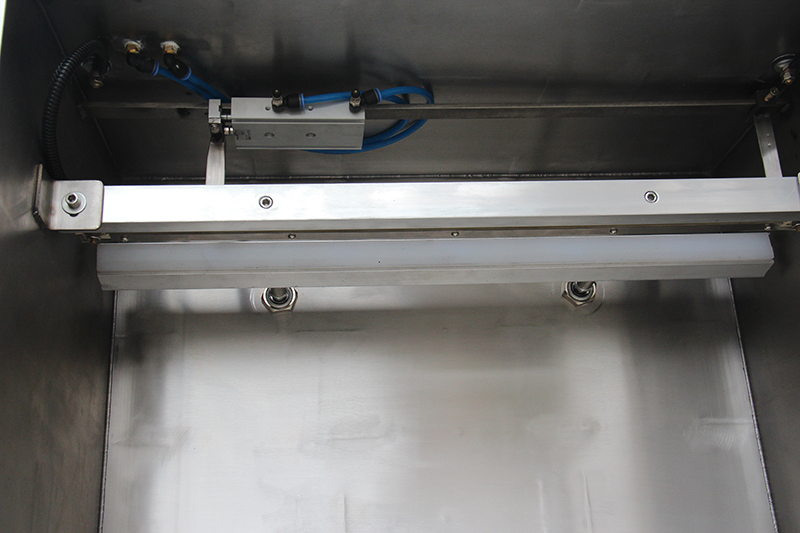

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation.

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Mode | DZL-420Y |

| Speed(cycles/min) | 6-8 |

| Packaging option | Rigid,or semi-rigid film,MAP |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <500 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 13.5 |

| Machine dimensions(mm) | 4600×1160×1900,Customizable |

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.