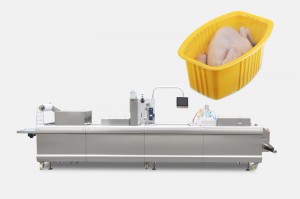

Fsc Series Continous Automatic Tray Sealer

Whether as a single packaging machine or integrated into highly automated and complex packaging lines include any automatic dosing and labelling units., Continuous automatic tray sealer from UTIENPACK are the ideal solution for high packaging volumes and can also be integrated into automated packaging lines in stages.

The accessible applications are numerous, from simple sealing to vacuum, MAP and various types and classes of packaging skin. The PLC touchscreen interface is simple and intuitive, making it easy to use even for inexperienced personnel. In addition, thehigh degree of customisation of the machine’scomponents ensures that it can be applied to any type of product to be packaged. Reliability, ease of cleaning and maintenance, easy programming and a wide range of customisation options are just some of its strengths.

1.Three packaging options: MAP, VSP and Simply Sealing.

2.High speed, high precision and accurate control with servo motor.

3.With imported German Busch vacuum pump, residual oxygen is lower than

1% of international standards.

4.Multiple sets of molds can be customized for different specifications.

5.Excellent packaging effect with UTIEN unique VSP (UniFresh®) technology.

6.304 stainless steel frame meets food hygiene requirements, durable and

easy to clean.

UTIENPACK tray sealers can handle different types of packaging in order to pack a wide range of products.

Natural atmosphere

This is a packaging type for no gas exchange, seal the packaging directly. There is no effect of extending shelf life.

MAP Pack

The natural gas in the package is replaced with the product-specific gas. This protects the product and also extends the shelf life of the food.

Pseudo-skin

The pseudo-skin technique applies to the product whose thickness is less than the tray depth. The skin film is applied to the product and sealed tightly in the tray.

Protrude Skin

The Protrude Skin technology packs products in a skin package, the height of the product can reach 50 mm. The packaged product is often higher than the tray.

This product is also precisely enclosed by the film and seals the tray on the whole surface.

Utien Pack Tray sealer is perfect for the package of fresh, refrigerated and frozen food, ncluding meat, poultry,seafood, sausages, bacons and prepared fast food.According to different products, we’re capable to offer you tailor-made packaging proposals.

1) Customizing capacity– 200~2,000 trays per hour.

2) Multifunction—vacuum gas flush, vacuum skin packing, or both combine.

3) Easy operation—by finger touch on PLC screen.

4) Reliable quality—spare parts of international top brands.

5) Flexible design— Various package shapes, volume, and output.

| Working Parameters | |

| Package Type | Sealing/MAP/VSP |

| Speed | 5-8cycles/min |

| Tray Quantity/mold | 3/4/6 |

| Tray Shape | Circular or Rectangle |

| Top Film | |

| Material | Sealable PEPA Multi-layer Co-extruded Plastic Film |

| Pre-printed Top Film or Transparent Top Film | |

| Roll Diameter | 250mm at most |

| Thickness | ≤200um |

| Components | |

| Vacuum Pump | BUSCH |

| Electrical Components | Scheneider |

| Pneumatic Components | SMC |

| PLC Touch Screen & Servo Motor | DELTA |

| Machine Parameters | |

| Dimensions | 3397mm×1246mm×1801mm |

| Weight | 800kg |