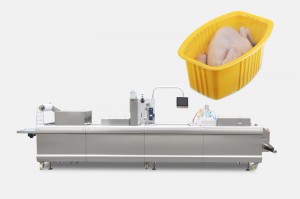

Form Fill Seal Machine

Form Fill Seal Machine

Security

Safety is our top concern in machine design. To ensure max safety for the operators, we have installed multiply sensors in many parts of the machine, including protective covers. If the operator opens the protective covers, the machine will be sensed to stop running immediately.

High-efficiency

High efficiency enables us to make full use of the packaging material and reduce cost & waste. With high stability and reliability, our equipment can reduce downtime, thus the high production capacity and uniform packaging result can be ensured.

Simple operation

Simple operation is our key feature as a highly automated packaging equipping. In terms of operation, we adopt PLC modular system control, which can be acquired through short-time learning. Besides machine control, mold replacement and daily maintenance can also be mastered easily. We’re keeping on technology innovation to make machine operation and maintenance as easy as possible.

Flexible use

To fit into various products, our excellent packaging design can custom the package in shape and volume. It grants customers better flexibility and higher utilization in the application. The packaging shape can be customized, such as round, rectangular and other shapes.With the most advanced technology of thermoforming system, packing depth can reach 160mm (max).

Special structure design can also be customized.

With the increasing diversity of food and its forms of expression, the packaging types of food are constantly changing. These various packaging forms can be reliably and effectively realized on the hot forming stretch film packaging machine. We can customize it according to your requirements.

Vacuum Pack

After vacuum, the package is tightly attached with the food surface. High vacuum package separates the food from outside environment, thus it prolongs shelf life of food.

MAP Pack

Mostly used in rigid film packaging, which is more protective than a vacuum pack. The product shape will not change due to the modified atmosphere.

Skin Pack

Unifresh Vacuum Skin Packaging, special body film like the second layer of skin close to the surface of the product, it is fixed on the hard tray. The film has strong tensile properties by heating.

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

- Multi-head weighing system

- Ultraviolet sterilization system

- Metal Detector

- Online automatic labeling

- Gas Mixer

- Conveyor system

- Inkjet printing or thermal transfer system

- Automatic screening system

1. Vacuum pump of German Busch, with reliable and stable quality .

2. 304 stainless steel framework, accommodating to food hygiene standard.

3. The PLC control system, making the operation more simple and convenient.

4. Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5. Electrical components of French Schneider, ensuring stable operation

6. The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

The regular model are DZL-320, DZL-420, DZL-520 (320, 420, 520 means the width of the bottom forming film as 320mm, 420mm, and 520mm). Smaller and bigger size thermoforming vacuum packaging machines are available on request.

Depending on the material used, packages can be flexible or rigid. Our thermoformers are suitable for vacuum pack, skin pack, and MAP technology, and the ideal solution for both food and non-food products.

| Model | DZL-R Series | DZL-Y Series | DZL-VSP Series |

| Speed(cycles/min) | 7-9 | 6-8 | 6-8 |

| Packaging option | Flexile film,vacuum&gas flush | Rigid,or semi-rigid film,MAP | Rigid film,skin packing |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

Rectangular and round, Basic formats and freely definable formats |

Rectangular and round, Basic formats and freely definable formats |

| Film widths(mm) | 320,420,520 | 320,420,520 | 320,420,520 |

| Special widths(mm) | 380,440,460,560 | 380,440,460,560 | 280 – 640 |

| Maximum forming depth(mm) | 160 | 150 | 50 |

| Advance Length(mm) | <600 | <500 | <500 |

| Die changing system | Drawer system,manual | Drawer system,manual | Drawer system,manual |

| Power consumption(kW) | 12 | 18 | 18 |

| Machine dimensions(mm) | 5500×1100×1900,Customizable | 6000×1100×1900,Customizable | 6000×1100×1900,Customizable |