Factory source Vacuum Chamber Food Sealer - Vacuum Packaging Machines – Utien Pack

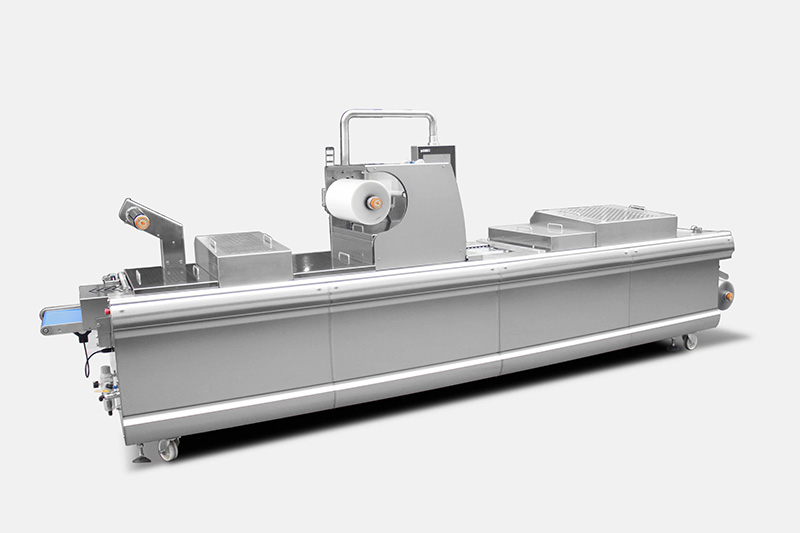

Factory source Vacuum Chamber Food Sealer - Vacuum Packaging Machines – Utien Pack Detail:

1. The whole machine is made of 304 food grade stainless steel, is easy to clean and corrosion resistant.

2. Vacuum and sealing are completed at one time, with PLC touch screen operation, vacuum time, sealing time and cooling time can be adjusted accurately.

3. Two vacuum chambers work in turn, with high production efficiency and high speed.

4. It’s compact & reliable, with wide application.

5. There are two types of sealing methods: pneumatic sealing and air bag sealing. The conventional model is air bag sealing.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for Factory source Vacuum Chamber Food Sealer - Vacuum Packaging Machines – Utien Pack , The product will supply to all over the world, such as: British, Lahore, Haiti, We have been making our products for more than 20 years . Mainly do wholesale , so we have the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we provide good products , but also because of our good after-sale service . We are here waiting for you for your inquiry.

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoform flexible film packaging machine extracts natural air in the packaging to extend the shelf life of the product.

As a common packaging solution, vacuum packaging can extend the shelf life of the product because the internal biochemical degradation of the package is slower in the vacuum-sealed state.

Advantages of Vacuum Packaging

-Longer shelf life of products;

-Convenient in storage and transportation as the package fits the product’s shape;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

Multi-head weighing system

· Ultraviolet sterilization system

· Metal Detector

· Online automatic labeling

· Gas Mixer

· Conveyor system

· Inkjet printing or thermal transfer system

· Automatic screening system

…

1. Vacuum pump of German Busch, with reliable and stable quality .

2. 304 stainless steel framework, accommodating to food hygiene standard.

3. The PLC control system, making the operation more simple and convenient.

4. Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5. Electrical components of French Schneider, ensuring stable operation

6. The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Mode | DZL-420R |

| Speed(cycles/min) | 7-9 |

| Packaging option | Flexile film,vacuum&gas flush |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <600 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 13.5 |

| Machine dimensions(mm) | 5100×1130×1900,Customizable |

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!