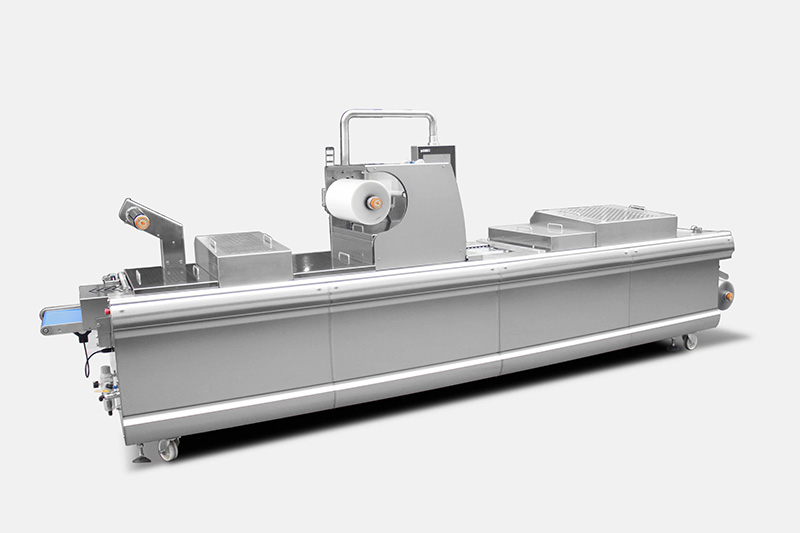

Factory Price For Food Vacuum Packaging Machine - Table Type Vacuum Packaging Machine – Utien Pack

Factory Price For Food Vacuum Packaging Machine - Table Type Vacuum Packaging Machine – Utien Pack Detail:

1.Using single-chip microcomputer series control, 9 groups of different parameter formulas can be stored, which can be flexibly recalled

2.The shell of the packaging machine is made of 304 stainless steel, suitable for various occasions and products packaging

3.The packaging adopts external vacuum packaging, the packing can be placed on the packaging table, which is easy to operate

4.The vacuum system adopts a vacuum generator, which has the advantages of no noise and no pollution, it can be used in a clean room.

5.Special specifications can be customized (The seal length can be customized and extended to 800 mm)

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for Factory Price For Food Vacuum Packaging Machine - Table Type Vacuum Packaging Machine – Utien Pack , The product will supply to all over the world, such as: Iraq, Hungary, Iran, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

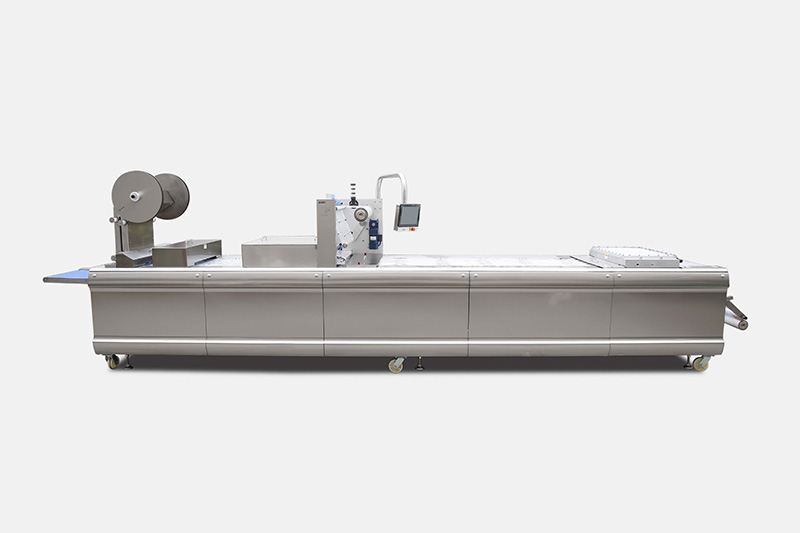

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoforming rigid film packaging machine is mainly used for modified atmosphere packaging (MAP) of products. The natural air in the packaging is replaced with fresh-keeping gases.

Advantages of MAP packaging

·Extend the shelf lifetime;

·Offer more protection during transportation;

·Keeping food fresh naturally without any additives;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

Multi-head weighing system

· Ultraviolet sterilization system

· Metal Detector

· Online automatic labeling

· Gas Mixer

· Conveyor system

· Inkjet printing or thermal transfer system

· Automatic screening system

…

1.Vacuum pump of German Busch, with reliable and stable quality .

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation.

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

| Mode | DZL-420Y |

| Speed(cycles/min) | 6-8 |

| Packaging option | Rigid,or semi-rigid film,MAP |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <500 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 13.5 |

| Machine dimensions(mm) | 4600×1160×1900,Customizable |

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.