Factory making Food Product Packaging Machine - Thermoforming vacuum skin packaging machines – Utien Pack

Factory making Food Product Packaging Machine - Thermoforming vacuum skin packaging machines – Utien Pack Detail:

Safety

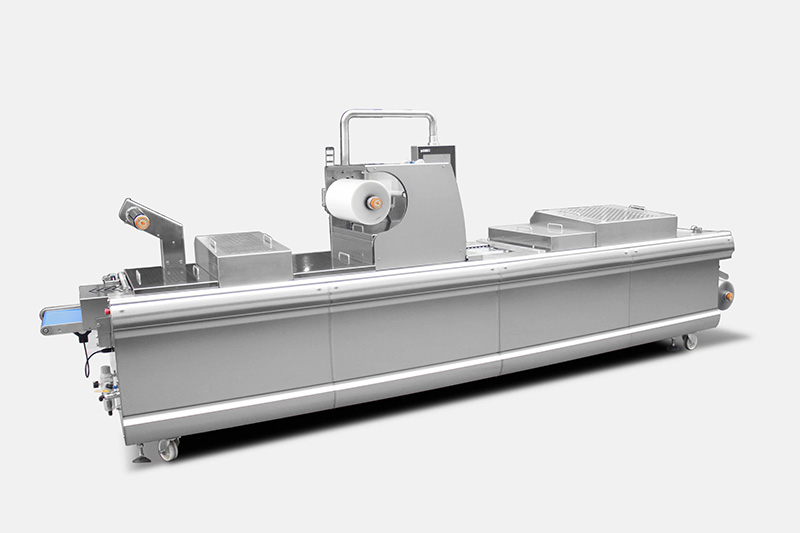

Safety is our top concern in machine design. To ensure max safety for the operators, we have installed multiply sensors in many parts of the machine, including protective covers. If the operator opens the protective covers, the machine will be sensed to stop running immediately.

High-efficiency

High efficiency enables us to make full use of the packaging material and reduce cost & waste. With high stability and reliability, our equipment can reduce downtime, thus the high production capacity and uniform packaging result can be ensured.

Simple operation

Simple operation is our key feature as a highly automated packaging equipping. In terms of operation, we adopt PLC modular system control, which can be acquired through short-time learning. Besides machine control, mold replacement and daily maintenance can also be mastered easily. We’re keeping on technology innovation to make machine operation and maintenance as easy as possible.

Flexible

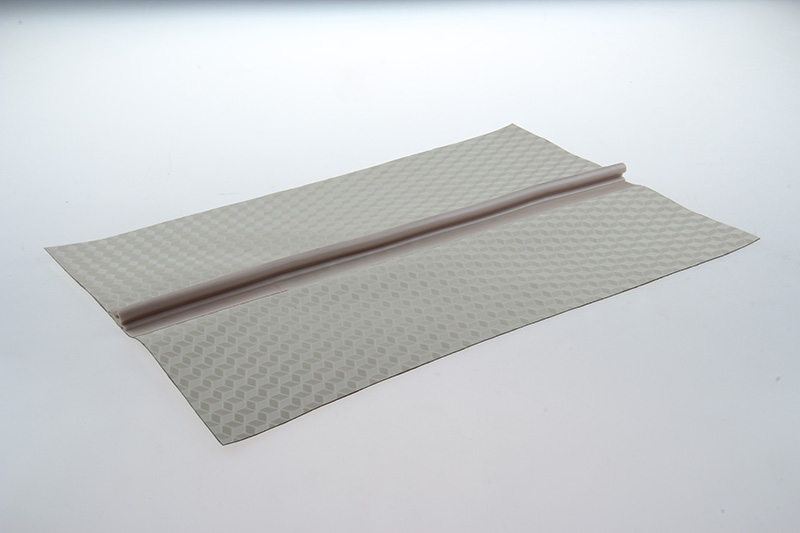

To fit into various products, our excellent packaging design can custom the package in shape and volume. It grants customers better flexibility and higher utilization in the application. The packaging shape can be customized, such as round, rectangular and other shapes.

Special structure design can also be customized, such as hook hole, easy tear corner, etc.

Product detail pictures:

Related Product Guide:

We consistently execute our spirit of ''Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for Factory making Food Product Packaging Machine - Thermoforming vacuum skin packaging machines – Utien Pack , The product will supply to all over the world, such as: Russia, Curacao, Miami, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

It’s able to handle a variety of thermoplastic material and poly-coated fabrics,such as tarpaulins, billboards,tents,awnings,inflatalbes,truck covers,and more.

Extension table

4 pieces in 1 set.Intend to hold the

banner whcih ensures that the two

end of the welding is smooth and

can slide to the next weld.

New measurement system

A block piece help placing the banner

Tape roller support with self brake

Suitable for overlap weld with tape on

one side.

Kedar holder

Hold the kedar to ensure the precise

weld with no deflection.

Laser light

Mark on the welding bar to show the

position where the banner should be.

Piston holder

A holding bar with piston pressure

which hold the position of the banner

incase that it moves before welding.

| Machine model | FMQP-1200/2 |

| Power(kW) | 2.5 |

| Voltage(V/Hz) | 220/50 |

| Air source(Mpa) | 0.6 |

| Sealing length(mm) | 1200 |

| Sealing width(mm) | 10 |

| Size(mm) | 1390×1120×1250 |

| Weight(kg) | 360 |

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!