Desktop Vacuum Packaging Machine

1. Controlled by PLC system, a variety of special functions can be flexibly used, and processes such as air extraction (inflation), sealing, and cooling can be completed at one time.

2. It adopts an nozzle retractable mechanism, instead of vacuum chamber. After vacuum, the nozzle will automatically exit the packaging bag, leaving the smooth sealing work. The speed of nozzle action can be adjusted.

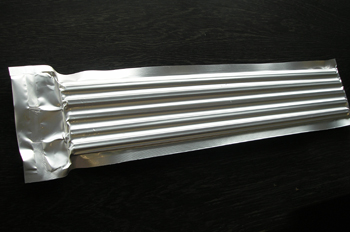

3. It is suitable for the vacuum (inflate) packaging of large-volume objects, and the sealing of various vacuum composite bags or vacuum aluminum foil bags, with good sealing effect and high sealing strength.

4. The external structure is made of 304 stainless steel, which is corrosion resistant and easy to clean.

5. Special specifications can be customized .

The machine is suitable for electronic products (such as semiconductor, crystal, TC, PCB, metal processing parts) to prevent moisture, oxidation and discoloration, etc. Food, fruits, vegetables, seafood and other products are added with inert gas to maintain freshness, original flavor, and anti-shock.

1.The whole machine is made of stainless steel, which meets food hygiene requirements.

2.The equipment adopts PLC control system, which is easy to operate and labor-saving.

3.Adopting Japanese SMC pneumatic components, with accurate positioning and low failure rate.

4.French Schneider Electric components guarantee long-term operation, increasing the reliability and durability of the equipment.

| Machine Model | DZ-600T |

| Voltage(V/Hz) | 220/ 50 |

| Power(kW) | 1.5 |

| Sealing Length(mm) | 600 |

| Sealing Width(mm) | 8 |

| Maximum Vacuum(MPa) | ≤-0.08 |

| Matching Air Pressure(MPa) | 0.5-0.8 |

| Dimensions(mm) | 750×850×1000 |

| Weight(kg) | 100 |