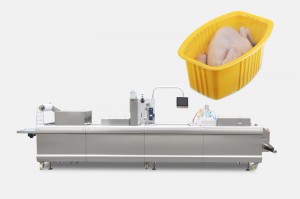

Poultry Thermoforming MAP Packaging Machine

Poultry Thermoforming MAP Packaging Machine

Safety

Safety is a top priority in the design of our machines, we have installed sensors in different parts of the machine including guards to ensure maximum safety of the operator.

High-efficiency

The efficiency of our equipment reduces downtime and maximizes packaging material utilization, resulting in consistent packaging and reduced cost and waste.

Simple operation

We offer simple operation thanks to our easy-to-learn PLC modular system control and allow for easy machine control, mold change and routine maintenance.

Flexible

Our packaging designs are flexible and can be customized in shape, volume and special structural designs, such as hook holes, easy tear corners and non-slip structures, to suit various products and applications.

Special structure design can also be customized, such as hook hole, easy tear corner, anti-slip structure, etc.

UTIENPACK provides a wide range of packaging technologies and packaging types. This thermoforming rigid film packaging machine is mainly used for modified atmosphere packaging (MAP) of products. The natural air in the packaging is replaced with fresh-keeping gases.

Advantages of MAP packaging

- Extend the shelf lifetime;

- Offer more protection during transportation;

- Keeping food fresh naturally without any additives;

One or more of the following third-party accessories can be combined into our packaging machine to create a more complete automated packaging production line.

- Multi-head weighing system

- Ultraviolet sterilization system

- Metal Detector

- Online automatic labeling

- Gas Mixer

- Conveyor system

- Inkjet printing or thermal transfer system

- Automatic screening system

- …

1.Vacuum pump of German Busch, with reliable and stable quality .

2.304 stainless steel framework, accommodating to food hygiene standard.

3.The PLC control system, making the operation more simple and convenient.

4.Pneumatic components of Japan’s SMC, with accurate positioning and low failure rate.

5.Electrical components of French Schneider, ensuring stable operation.

6.The mold of high-quality aluminum alloy, corrosion-resistant, high-temperature resistant, and oxidation-resistant.

The regular model are DZL-320R, DZL-420R, DZL-520R (320, 420, 520 means the width of the bottom forming film as 320mm, 420mm, and 520mm). Smaller and bigger size thermoforming vacuum packaging machines are available on request.

| Mode | DZL-Y Series |

| Speed(cycles/min) | 6-8 |

| Packaging option | Rigid,or semi-rigid film,MAP |

| Pack types | Rectangular and round,Basic formats and freely definable formats… |

| Film widths(mm) | 320,420,520 |

| Special widths(mm) | 380,440,460,560 |

| Maximum forming depth(mm) | 150 |

| Advance Length(mm) | <500 |

| Die changing system | Drawer system,manual |

| Power consumption(kW) | 18 |

| Machine dimensions(mm) | 6000×1100×1900,Customizable |