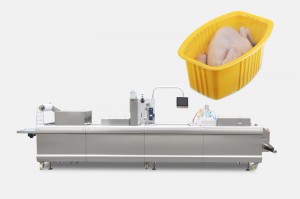

Automatic Contİnuous Tray Sealer FSC-400

Whether as a single packaging machine or integrated into highly automated and complex packaging lines include any automatic dosing and labelling units., Continuous automatic tray sealer from UTIENPACK are the ideal solution for high packaging volumes and can also be integrated into automated packaging lines in stages.

The accessible applications are numerous, from simple sealing to vacuum, MAP and various types and classes of packaging skin. The PLC touchscreen interface is simple and intuitive, making it easy to use even for inexperienced personnel. In addition, thehigh degree of customisation of the machine’scomponents ensures that it can be applied to any type of product to be packaged. Reliability, ease of cleaning and maintenance, easy programming and a wide range of customisation options are just some of its strengths.

1.Three packaging options: MAP, VSP and Simply Sealing.

2.High speed, high precision and accurate control with servo motor.

3.With imported German Busch vacuum pump, residual oxygen is lower than

1% of international standards.

4.Multiple sets of molds can be customized for different specifications.

5.Excellent packaging effect with UTIEN unique VSP (UniFresh®) technology.

6.304 stainless steel frame meets food hygiene requirements, durable and

easy to clean.

MAP, Modified Atmosphere, Vacuum & Gas flush

VSP Vacuum Skin Pack

FSC-400 Continuous Tray Sealer Machine can meet the packaging needs of large-scale production. With a professionally designed tray feeding mechanism, it can run continuously, significantly enhancing packaging efficiency. Based on varying packaging requirements, multiple sets of mold is optional for different products. Utien offers comprehensive and specialized packaging solutions tailored to client specifications.

|

|

|

|

|

|

Utilizes servo motor control for fast speed, high precision, and excellent controllability.

Uses German Busch vacuum pumps, with oxygen residual below 0.4%.

High customization with multiple mold sets.

Utien’s unique skin pack technology (Unifresh ) ensures outstanding packaging results.

The machine body is made of 304 stainless steel, which is corrosion-resistant and easy to clean.

| Machine Parameters | |

| Machine mode | FSC-400 |

|

Packing speed Cycles/min, MAP Cycles/min, Skin Pack Cycles/min, Top Seal |

6-8 6-8 10 |

| Power(kW) | 18 |

| Machine dimension(mm) | 3410×1121×1857 |

| External diameter of the film roll(mm) | ≤300 |

| Max depth | 160mm ( depends) |

| Power voltage(V/Hz) | 380/50 or Customized |

| Oxygen residual for MAP | ≤0.4% |

| Gas option | N2, CO2/N2, O2/CO2/N2 |

| Top film | Transparent top film, pre-printed top film |

| Packaging applications | Fresh foods, cooked foods, seafood, frozen products, ready meals, fruits and vegetables… |